Your Source for Premium Hardwood Lumber

Featured Items

Check out our top product offerings for your next woodworking project.

| Species: | MAPLE (HARD MAPLE) |

| Type: | Dimensional Lumber |

| Width: | 2.5", 3", 3.5", 4", 4.5", 5", 5.5", 6", 6.5" |

| Length: | 18", 24", 30", 36", 42", 48" |

| Species: | CHERRY |

| Type: | Lumber Squares |

| Width: | 4/4 (13/16"), 5/4 (1-1/16"), 6/4 (1-5/16") |

| Length: | 12", 18", 24", 30", 36" |

| Species: | Walnut |

| Type: | Thin Stock |

| Thickness: | 3/8" Walnut |

| Width: | 3", 3.5", 4", 4.5", 5", 5.5", 6", 6.5" |

| Length: | 12", 18", 24", 30", 36", 42", 48" |

North Castle Hardwood

MORE ABOUT NORTH CASTLE

Our company owners have been providing the highest quality custom graded lumber to the Japanese furniture market for over 30 years.

Discover Woodworking

Learn tips & techniques for working with hardwood lumber.

Surfaced Lumber Guide: What does S2S, S3S and S4S Mean?

Like many crafts, woodworking comes with its own dialect. Some of the language of lumber can be tricky to get used to. But many terms that seem technical – such as S2S or S4S – are actually simple to understand and use as you plan your next woodworking project. What does S2S, S3S, and S4S lumber mean? Designations S2S, S3S, and S4S tell you the level of milling that has taken place on a board. In these terms, the first S means “surfaced” and the second “S” means sides. The number tells you how many sides have been surfaced. What does “surfaced” mean, when referring to lumber? It means that the board has been milled or planed to create a smooth surface, free of saw marks or rough edges. What Does S2S Lumber Mean? “S2S” lumber means “surfaced two sides.” S2S boards have two finished surfaces, usually the widths (faces) of the board opposite each other, with the edges left rough. They are ideal for projects that may have a requirement for variable-width boards. S2S lumber can be used to exploit a rustic look to the edges, or you could use a bandsaw to follow an uneven, natural shape along the length of the grain. When a project only has one or two finished sides to be visible, and you’re okay with some variance in width and length, S2S lumber is the type to choose. To use S2S lumber in fine woodworking projects, you’ll need to do some of your own milling or planing in your home or shop. Where to Use S2S Lumber S2S is great for construction or structural work. If you like to do a little bit of your own milling, then S2S is a great time-saver over using rough cut lumber. You get to see the figure and grain straight off without the back-breaking work required to take it from rough to finished. What Does S3S Lumber Mean? It follows then that S3S lumber has been finished on three sides, with one edge ripped nice and straight. One edge may still be rough cut, but in many woodworking projects, some surfaces are never seen, so S3S becomes a practical and economic choice. S3S boards give a woodworker the choice of flexibility when it comes to custom widths or shapes. Why pay more for a finished edge that will end up in the off-cuts bin? At North Castle Hardwoods, we offer S3S lumber packs in two grades: clear one face (C1F) and clear two face (C2F) to help you maximize efficiency on your project. Where to Use S3S Lumber Shelves and bookcases, which have one face against a wall, are ideal projects for S3S lumber. With one rough edge, adjustments for depth are easy: for example, scribing a shelf to an uneven stone, or a brick-finish wall. What does S4S Lumber Mean? S4S lumber has been finished on both faces and both edges, which should mean that the boards have four perfectly square corners. The length and width of the board can vary, of course. S4S lumber is different from a lumber square, where the width and thickness of the board are the same measurement. S4S is a popular choice among hardwood woodworkers. The lumber is ready for use in a wide range of standard projects and is of a consistent shape and size. Where to Use S4S Lumber Dimensional S4S lumber is ready to use with a minimal amount of preparation or work. Use it on furniture and cabinetry projects, or for cutting boards and any fine woodworking project. If your time is limited, or you don’t have the necessary milling hardware of a planer or jointer, then S4S lumber is the way to go. Why Can’t You Buy S1S Lumber? Surfacing just the one side of a board sounds like the economic thing to do if you only want a finish on say the top of a cabinet, or on the face of wall paneling. However, lumber is a natural material that reacts to changes in humidity. By finishing just the one side, the rate of drying becomes unequal, and the board will likely cup and bow. Is Big-Box Store S4S Lumber Worth It? Most of the lumber on the racks at your local DIY store will be S4S milled wood. It’s easier to handle, cleaner to move and set out for customers than rough cut lumber or S2S. The problem is that the transport and storage of much of this low-grade lumber sometimes leaves a lot to be desired. Oftentimes it has been exposed to humidity, and it has not been stacked properly. This is why it will show up cupped, warped, and twisted. Finding a nice, straight piece of wood with minimal defects can be a challenge, especially if you’re shopping for hardwood species. The North Castle Difference At North Castle Hardwoods, we have generations of experience in selecting, seasoning, and milling American lumber. All of the S4S lumber on our racks has been meticulously sorted for quality and stored with utmost care. Call or visit us today to pick out premium S2S, S3S, or S4S hardwood lumber you can rely on.

Lumber Sizing Explained: Rough Cut to Finished Dimensions

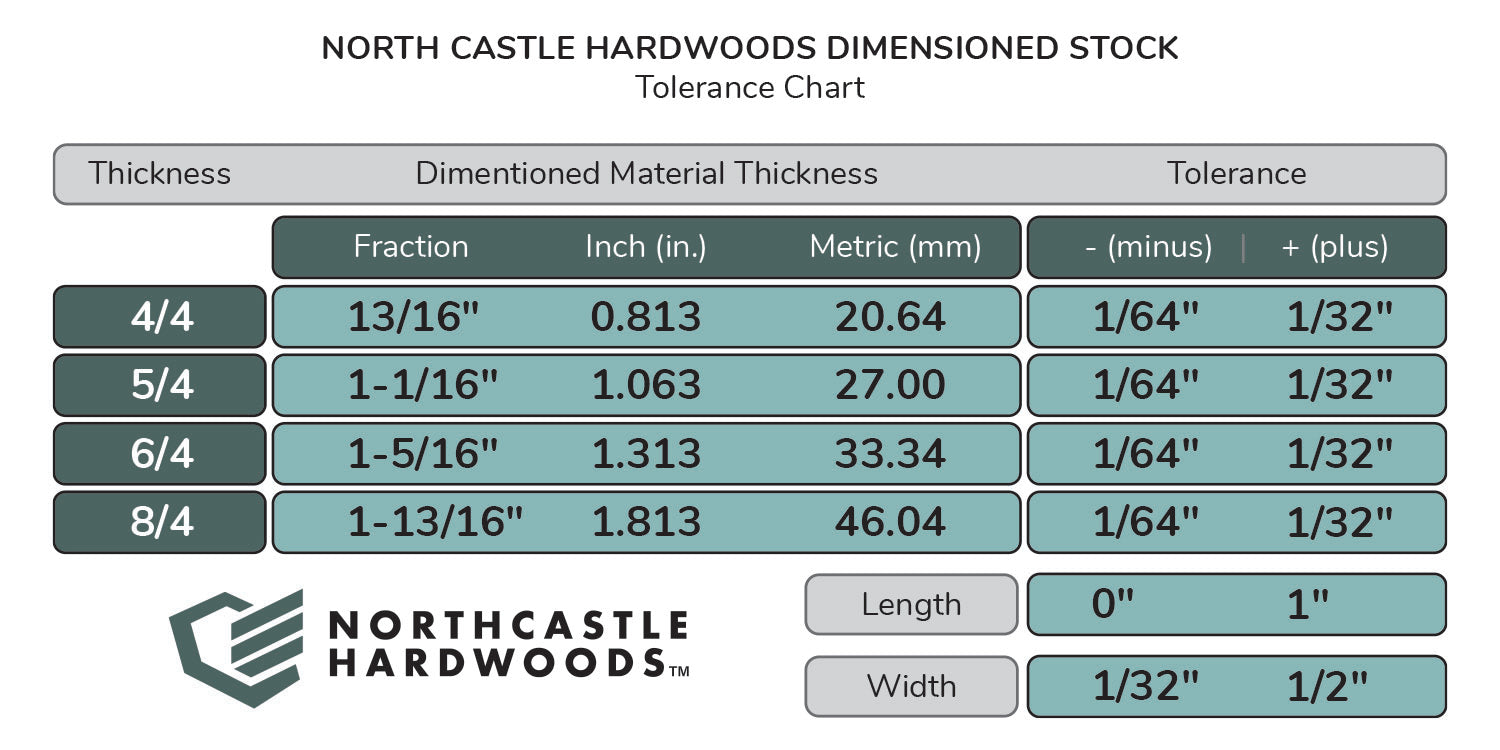

There’s some industry terminology to wrap your mind around when understanding lumber sizing. If you place an order of rough cut lumber, the actual board measurements may differ from your expectations – but there are logical reasons for this. So what does lumber sizing mean, and how do rough cuts compare to finished dimensions? Nominal vs. Actual Dimensions Lumber is often referred to by its nominal dimensions – that is, the dimensions to which it was cut before drying, planing, or finishing. So when we refer to a piece of lumber as a “two by four” (2x4) - that means it was cut to be 2” thick by 4” wide – not that it’s that size when you buy it from the store. Builder grade 2x4’s actually measure 1.5” x 3.5” when you buy them at a lumber yard. Premium grade lumber, such as the kind we offer at North Castle Hardwoods, is sometimes sold the same way. Our 8/4 thick stock, for instance, measured 8/4 thick – that is, two inches – when it was cut. But after drying and finishing, it measures about 1 and 13/16 inches (1.813”) thick. So, in this example, the “nominal” dimension is 8/4, but the “actual” or “finished” thickness is 1.813”. At North Castle Hardwoods, we have very tight tolerances on our dimensioned lumber products. This means that, if you buy a piece of lumber that we say will be finished to 13/16”, the actual thickness of that lumber will be within a 1/32” margin of 13/16”. What do the terms 8/4, 6/4, 5/4, or 4/4 lumber mean? The terms 8/4, 6/4, 5/4, and 4/4 refer to rough cut lumber thickness. Lumber thickness is measured in quarters of an inch. So 4/4 lumber is cut to be 4/4 of an inch thick – or 1 inch thick. 6/4 is rough cut to 1.5 inches thick. 8/4 and 6/4 are often considered “thick stock” lumber. Anything with a thickness of ½” or below is considered “thin stock.” See the chart below. Designation Rough Cut Thickness Finished Thickness (Approx) 8/4 2 inches 1.813 inches 6/4 1.5 inches 1.313 inches 5/4 1.25 inches 1.063 inches 4/4 1 inch 0.813 inches These terms have nothing to do with the length or width of lumber. 4/4 boards can be cut to any length or width. It’s important to keep in mind that the length and width dimensions listed on lumber for sale may be nominal or actual. Rough Cut vs. Finished or Dimensioned Lumber So when you’re buying lumber or calculating how many board feet you will need for a woodworking project, it’s crucial that you know whether the boards you are buying are being sold with nominal (i.e. rough cut) or finished dimensions. Check whether the lumber you’re buying is sold as S2S, S3S, or S4S. S2S and S3S lumber has been surfaced to an exact dimension on two or three sides. The other sides, those that aren’t surfaced, are left rough and can vary in their exact dimensions, often up to ½” or more. The length of the board can also vary up to an inch or two. Check the seller's website for exact details, since different mills have different tolerances. Here at North Castle Hardwoods, we call our S4S lumber “dimensioned” hardwood, because it has been planed or surfaced on all four sides, so you know nearly exactly the thickness and width of the board you are getting. All four surfaces of the board are straight and ready for use in a project without further planing. Buying S4S lumber doesn’t mean you won’t have to cut the board at all for your project, since widths and lengths have tolerances of ½” to 1”. But you definitely won’t get less wood than you ordered, because you can calculate based on actual (finished) dimensions, rather than rough dimensions. Why are finished dimensions of a board smaller than nominal dimensions? If you calculate how much lumber you need for a project based on rough cut dimensions, you may come up short. When wood is dried, it loses a huge percentage of its moisture. Depending on the species, green lumber may have more weight in water than in wood mass. Air-dried lumber should be 15-20% water, and expertly kiln-dried lumber has a moisture content of only 6-8%. While the weight of a board changes with drying more than length, width, or thickness does, these dimensions are also affected. Even after drying, lumber is a natural product, and is prone to atmospheric changes, such as humidity, which affect the size and shape of a piece of wood. After drying, wood may be planed to create a smooth flat surface, remove imperfections, and/or to standardize sizing. This brings the size of the board down a bit more. So What is Rough Cut Lumber? Rough cut lumber is timber that has been sawn but not finished. It’s the wood you will find at the sawmill or lumber yard before it goes off to be further processed. It will likely have saw marks and other imperfections from being cut to size. Rough cut lumber is less expensive than dimensional lumber because of the lack of processing, milling, and treatment. Its main use is in framing buildings where a fine finish is not required. When the lumber is enclosed within a wall it doesn’t matter what it looks like. Some woodworkers like the rustic look that rough cut lumber can give. Others enjoy carrying out the milling work themselves to get the right dimensions for their own project. Partly-finished lumber that retains some textural elements left over from the band saw can suit some woodwork projects. We love S3S lumber, because it’s been surface planed on both faces with a straight-line rip on one edge. The other edge is left rough. This gives the woodworker maximum width and thickness to work with, but makes it easier to get straight edges than it is with rough lumber. Rough cut lumber is often sold by the board foot, as sizes can be irregular. At North Castle Hardwoods, we have tolerances in place to make sure you know what size board you’re ordering. But if you’re shopping at a local mill, always take a tape measure with you so you can be sure you are getting what you came for! The downside to using rough cut lumber for finished work is that it does take a fair bit of work to get to a point where it is usable. You might use it to put together a shop workbench or a rustic outdoor bench and table set. But for fine indoor furniture, rough cut lumber isn’t the best choice unless you have milling and planing equipment of your own. What is Finished Dimensional Lumber? Finished dimensional lumber is what you find on the racks at your local lumber yard or big box DIY store. It’s timber that has been through all the processes required to turn it into a ready-to-use finished product. It will be planed and squared and cut to specific shapes, from rectangular, to square, to tongue and groove planks. The worst defects have been cut off and left behind. Split, waney-edged, and damaged lumber rarely makes it onto the racks if you buy from a reputable supplier. As a result, dimensional lumber will cost more than rough cut lumber – but you’re getting a better value. Which Lumber is Right for Your Project? Rough cut is cheaper, but it will cost you more time to prepare it for use in woodwork projects. Pine is easier to mill at home, as it is a softwood. Hardwoods such as oak, cherry, or maple are much harder and require much more specialist tools. Hardwood can be quite unforgiving, especially if your tools aren’t as sharp as they could be. So if you’re shopping for hardwood, especially, you’ll benefit from buying finished or partially finished boards. The moisture content will be consistent, and the size and performance will meet your expectations. At Northcastle Hardwoods, the quality of the dimensional lumber is never in question. Pay us a visit, or order online today.

Protect Your Natural Wood Furniture: Cleaning & Care Tips

When you have beautiful, natural wood furniture, you want to keep it looking as good as the day you got it! Our cleaning and care tips will help keep your furniture looking as beautiful as the day you brought it home. How To Care For Your Natural Wood Furniture Taking care of your natural wood furniture can be as simple as where you place it in your home, or using a coaster. While it is easy to care for, it is important to care for it properly to ensure a long lifespan and continued beauty. Seal Your Furniture Sealing your furniture is important not just to create a barrier against moisture. Sealants can also protect wood from scratching, warping, and cracking. It can even help reduce the effects of UV rays. A simple coat of sealant can help extend the life of your furniture by years! Keep Out Of Sunlight Sunlight is the enemy of wood furniture, even when kept inside! The color of natural wood can fade when exposed to too much direct sunlight. The heat can dry out the wood, leading to cracks, warping, or even melting the finish. Try to position wood furniture away from windows. If your furniture will be exposed to a lot of sunlight, seal it first to provide some protection. Use Trivets Placing hot dishes directly on wood can cause burn marks, scorch marks, or stains. Heat can also melt the finish of your furniture. It is important to always use a trivet or even an oven mitt before putting hot dishes down to protect your wood furniture. Use Coasters No one wants to see unsightly water rings on their beautiful wood furniture. Be sure to use coasters, and if you see any standing water, wipe it up immediately. Choose coasters with soft, non-abrasive bottoms to avoid scratching the wood. Manage Humidity Humidity is the enemy of wood furniture, with the ideal humidity range between 40 and 45 percent. In some areas, you may need to run a humidifier in the winter to combat the dry air, which prevents the wood from drying out and shrinking. Likewise, some climates may need a dehumidifier in the summer to avoid too much moisture, and to keep the wood from swelling and warping. Avoid using wood furniture in humid basements – unless you use a dehumidifier to keep the moisture levels under control. Lift, Don’t Drag When picking up an item from your table, always lift – don’t drag it! This will help avoid scratching or gouging the wood. Even something light and small, like a coaster, can damage wood if dragged across the furniture, especially if it doesn’t have a soft covering on the bottom. How To Clean Your Natural Wood Furniture Another important way to care for your furniture is to clean it properly. While it may be tempting to grab the closest thing at hand, the right care will keep your furniture looking wonderful for many years to come. Clean With Soap & Water Cleaning your natural wood furniture couldn’t be more simple! Use a mild dish soap and a damp, not dripping, washcloth or sponge. After gently cleaning your furniture, wipe it down with a clean, damp washcloth. Finally, dry the furniture with a dry washcloth. Clean Spills Immediately You never want to leave moisture sitting on your wood, nor do you want to allow the table to remain dirty or sticky. Clean spills promptly to avoid staining or cracking, and be sure to dry the wood afterward. You should never submerge your wood furniture in water, so remember if you do need to use water, stick to a damp cloth. Polish Polish helps protect the wood, as well as keeping the wood shiny and beautiful. After each cleaning, be sure to polish your furniture to help replace the polish that inevitably wore off. You can use an all-purpose cleaner if you need to remove stains before you apply a new coat of polish. Dust Regularly Dusting your furniture regularly prevents dirt and grit buildup. Be sure to use a soft, dry cloth or duster. Avoid paper towels, as they can lead to scratches on the furniture, especially when dry dusting. Avoid Harsh Chemicals Avoid using harsh chemicals like bleach or ammonia on your furniture. Cleaners that contain chlorine, as the ones mentioned do, can damage the finish on your furniture. Over time they will cause staining, discoloration, or even cracking! Care For It Now, Love It For Life Natural wood furniture offers many colors and ways to incorporate its elegance into your home, no matter your preferred decor style. With proper care and cleaning, you’ll be happy with your furniture for years to come. North Castle Hardwoods Is Here To Help At North Castle Hardwoods, we believe in providing quality, sustainable wood for all your project needs. We also look for the best products to keep your wood projects amazing, like this finishing wood wax, safe for everything from cutting boards to furniture. We’re here to help, whether you want to take advantage of our expertise in providing wood to top Japanese furniture makers for the past 30 years, or you want to browse our articles on a variety of wood-related topics. If you have a question, please reach out to us today! Our experts are here to help you.

Why You Should Choose Natural Wood Furniture for Your Home

Whether you are a traditionalist or have an eye for modern design, natural wood is a great choice for home furnishings. With its versatility and aesthetic good looks, natural wood furniture never goes out of style. Solid wood furniture can stand the test of time and is often handed down through the generations. Choose natural wood for its robust performance, strength, and utility. Hardwood is a sustainable choice too with lumber grown right here in the Mid-West. At North Castle Hardwoods, we know wood, and what it can do. What is Natural Wood Grain Furniture? Natural wood grain furniture is made from sections of solid lumber, machined, and sometimes finished by hand. The nature of wood means that no two pieces will be identical, as the way it was grown, or cut, will produce differences in the lumber. Some species are used for their regularity. Maple is a bright-grained wood that has a uniform appearance and is popular in modern industrial furniture design. Oak and cherry, on the other hand, are renowned for their individual character and are widely used for feature tabletops, and other traditional furniture projects. Eight Reasons to Use Natural Wood for Furniture Only eight, you say? Well, eight is plenty, but the main reason for us comes top of the list. It's Beautiful Top of the list is the unarguably definitive reason that real wood is beautiful. It has a depth of color, and reflective texture that exudes warmth and quality. The wide variety of grain colors, from the pale yellow of maple to the deepest cherry red, to rich dark chocolate walnut and oak tones, is remarkable. Finished with proprietary waxes, or oils, the beauty of the wood grain becomes almost three-dimensional, infused with the light of many summers growth. Some lumber, like oak, has a complex grain that delivers gloriously repeating patterns. It's Long-Lasting Natural wood furniture is not just robust and long-lasting, but, unlike some of us, it gets better looking as the years roll by. Colors deepen, and a patina of age can make the wood grain seem richer. If a piece of solid wood furniture has been badly finished with varnish or paint, it doesn’t take much to get it looking amazing once again. With a little effort with sandpaper and a finishing product, it can be back to looking good as new in no time. I have a table that was made by my uncle just after WWII. He and my aunt dined at it every day of their long marriage, and now it sits in our home. We also own an oak side table that his grandmother used. Both are in excellent condition. The side table was rescued from a paint shop, cleaned, sanded, and waxed! It's Unique No two pieces of wood are exactly alike. Hardwood and softwood grains each have different qualities that make them suited to different jobs. Even mass-produced pieces of wooden furniture that have to aspire to a uniform aesthetic, and attain common quality standards, will each be unique. A pair of bedside tables might match, in that they are made to the same design, but look closely at the door front, at the drawer, and at the top. They will each differ to some degree depending upon the regularity of the grain. Brings Nature Inside The benefits of the natural world with regard to our mental health and general well-being have long been documented. However, we aren’t all lucky enough to be able to go for walks in the forest every day. Real wood can help us to feel that same connection to the forest that we experience when we get out into a national park or sports field. The natural forms framed by a piece of solid wood furniture, the colors of the grain, and the way it flows within the structural necessity of furniture. Offers Easy Maintenance Solid wood is easy to look after too. Keep it dry, dust it, and perhaps give it the occasional polish to keep it looking great. If a piece of wooden furniture is damaged it can be easily repaired. A scratch can be sanded out, stains polished away, and broken parts renewed. Once a plastic laminate surface has been chipped, or marked, that’s it. It will never look like new ever again. Real wood, on the other hand, can be burned, painted, or otherwise mistreated, and still be revived to its former glory with a little time and care. Retains Value A well-made piece of natural wood furniture will keep its value for years. Mid-century furniture has recently had something of a revival. If you have a chair, side tables, or a cabinet in the back of the garage that belonged to your parents, or grandparents, it might be worth something today. The same goes for any investment in solid wood furniture you make right now, whether purchased from a local store or workshop or made at home, in your own shop. Real wood furniture is usually very well made and will hold its value over the decades. It Matches Any Interior Style Do you have eclectic taste, enjoying a mix-and-match approach to home décor? Or are you someone who likes to live with a theme? Whatever your style, traditional, modern, or avant-garde, real wood is versatile enough to take on all your fancies. The thing with natural wood furniture is that it is quality, and quality my friend, never goes out of style. I have a utility-style table in the great room that we use for hobbies, made from pink and yellow piranha pine. It doesn’t match anything else in the house, but it looks perfect where it is. It's Sustainable Wood is one of the best-managed, most sustainable resources on the planet. As it grows it captures carbon while providing a habitat for wildlife. Cherry trees also provide food for birds, and people, every summer. Oak grows particularly slowly, but as a resource is carefully stewarded by professional foresters ensuring that future generations can also benefit from using quality lumber. The fast-growing American black cherry tree is used to rehabilitate land that has suffered from mining or other industrial use. By filling your home with natural wood furniture, you become part of this sustainable cycle, whether purchasing new, or upcycled pieces or making your own custom creations. Tips for Using Natural Wood Working with wood is one of the joys of being on planet Earth. It really is an amazing material, which you can bend, cut, and fashion to whatever you want. The versatility of lumber means that you can use it to make almost every functional piece of furniture you need. The five top tips I have for using natural wood are these: Always make sure your tools are clean and sharp. Always have more than one tape measure, they disappear at will. Always keep your pencil point keen, and mark gently. Always stack and store your lumber carefully so you can see what you have. Always take time to enjoy what you are doing. We Sell Natural Hardwood! At North Castle Hardwood, one of the best parts is picking out the lumber for a project. You are always welcome to come down to our depot and spend time looking through our selection of top-quality natural wood. We have been supplying hardwood locally for more than three decades, to furniture workshops here in the Mid-West, and beyond, to the master furniture makers of Japan. Do we send them the best stuff? Of course we do, but not all of it. We have a huge range of fantastic North American-grown lumber for you to choose from. If you can’t make it to our depot, call us. We can dispatch hand-picked pieces direct to your door.

Cool Woodworking Projects for Experienced Woodworkers

When you really get going there’s no holding back when it comes to potential cool woodworking projects that you can take on. All you need is a little patience and practice, to achieve wonders. We all start off with small jobs, like making a shelf unit or putting something together for the workshop or home. It’s easy to get the bug and want to do more. At North Castle, we can help. We have years of experience on tap to support you on your woodworking journey. Check out these advanced woodworking projects that will build your confidence when planning your own woodworking expertise. Our Top Advanced Woodworking Projects When making plans for any project you can let your imagination run riot. Wood is a fantastic, natural resource that can bend to the will of anyone with the patience, space and time to spare. At North Castle, we’ve been doing this a long time, and are happy to help with any questions you might have. Take a look at our top advanced woodworking projects below. Workbench Every woodworker needs a strong base from which to put together their plans. The only way to properly facilitate your cool woodworking projects is if you have a suitable workbench as a launchpad. All you need are some decent solid lengths of 4 x 2 to build the frame, which can come from anywhere, as long as the lumber is clean. It’s best to buy lumber for the top as you don’t want a scrappy finish to work on. The best thing about building your own workbench is that you can customize it to fit your workspace exactly. Start with a basic plan, and customize it accordingly. If your workshop has multiple uses, you can fit heavy-duty, locking casters to the base so you can move it around. Office Desk Once your workshop is ready to go the sky is the limit. If you have a desire to work with some fine finish materials, but don’t want to go for the family dining table straight away, then an office desk woodworking project will get you limbered up with the good lumber. Desk plans come in all shapes and sizes, from utilitarian to fancy, but the common theme is functionality. The finish to the desktop is important, but this project will also challenge other skills, such as putting together drawers with box joints. There are nominal standard heights for furniture, which is great if the person you are making it for is a standard human. The best thing about building an office desk yourself is that you can customize it for its user, perfect if they’re either over 6’ or below 5’. Dining Room Table I have an heirloom dining room table made by my uncle in his workshop in the 1960s. It’s in the garden room and is a favorite spot for the cats to sit and sun themselves. It’s a simple design, but the finish must have taken him days to perfect. He used contrasting lumber to give it a color counterpoint. At North Castle, we have a wide selection of hardwoods that you can use to deliver a similar effect. Our hard American Maple is a tough customer to work with, but rewarding, and will stand any test of time. Again, the good thing about this advanced woodworking project is that it is entirely customizable to the space it will inhabit, and the folks that will sit around it. Of course, you can have the most fun turning traditional table legs on a lathe. Handmade Chess Set We’re not suggesting that you hand-carve an entire set of pawns, queens, rooks and castles! That would be quite a stretch for most of us, but a chessboard is an achievable and very cool woodworking project to do. It’s also an opportunity to try out your precision cutting and finishing skills. With one or more of our lumber packs, you can choose the perfect contrasting species to get the best effects. A classic chess board design might also include storage for the chess or draughts pieces, while also being an eye-catching piece of work. This plan, from the Woodworker’s Journal, will speak volumes regarding your skill and patience as a player. Kitchen Island We’ve all seen the reels on social media showing Ikea hacks, and how to make a kitchen island from computer cut-out panels, but we all know there’s no substitute for a well-made hand-crafted piece of kitchen furniture. Your kitchen is the heart of the home, where families come together to eat, and talk about the day. A good kitchen island can be a food workstation, a dining area, and deliver essential storage. With kitchen island designs you can go full-on pioneer farmhouse, make it rollable for repositioning wherever you want, and build it to exactly the dimensions you need to fit your space. Custom Bed Frame The Mozart opera ‘The Marriage of Figaro’ opens with a man, on his knees, measuring up a room for the bed he will share with his wife. It used to be the way we all selected our furniture, from pioneering days on. But putting a custom bed frame together is not a difficult project to master. At the end of the day, if you have successfully built a workbench, then most furniture projects are simply a variation on the theme. One key mistake that is very easy to make: is access and logistics. Most large bedframes won’t be easy to move once assembled. Check that the bed you make will fit through the doorways, corridors and staircases of your home, or assemble it in the room! Bar Cabinet There’s an old saying from 18th-century England that goes, ‘Those who purchase a house, open a tavern for their friends’. This is true up to a point, especially if you are a sociable sort, or have a large circle of friends and family. And it’s when you host an event that you can also take a little pride in displaying your cool woodworking projects. It’s nice to be able to create useful things with beautiful hardwood lumber, and even better if you can share those accomplishments. Bar or display cabinets are where you can indulge in your sense of elegant design. The timeless grain and quality of oak, or walnut lends itself to the finishes demanded of fine great room furnishings. Porch Swing Fall and Winter are great months to get on with outdoor projects so that they are ready for when you want to start enjoying them. There’s nothing better on balmy Summer evenings, or on those fresh Spring mornings than sitting out on the porch in a swing seat or other outdoor furniture. Better still if you are out there, sipping on your coffee or morning tea, and sitting on something you put together yourself. What a satisfying way to start the day. Always make sure that the support is adequate overhead for any suspended swing furniture! If you like the idea of a porch swing, and you don’t have a porch, then you can always hang a swing from an A-frame and locate it wherever you want to sit and contemplate the view! Backyard Storage Shed Self-storage is one of the top growth areas in business in the USA today. Homes are getting smaller, while the need to store our stuff is apparently a growth industry. I can’t think of a better way to solve this problem and free up storage for lumber and other good things, than putting a storage shed together. Whatever size backyard you have, there’s always one area that will be perfect for a storage shed, tucked up against the back fence, or down beside the house. The key to making a shed a success is ensuring that the base foundation is solid and that there is good drainage. We don’t recommend that you use premium hardwood for your outdoor buildings as treated softwood will be more than adequate. However, by taking your advanced woodworking knowledge and applying it to a generic storage shed plan, you can probably come up with something as bespoke as you need it to be. Our S3S Lumber Packs are Perfect for Advanced Woodworking Projects What is an S3S Lumber pack? Simply put, it’s a selected pack of lumber that is finished on three sides, to make joining lumber, and assembling pieces a faster, and more satisfying experience. Milled to exceptionally good quality for lumberyard material S3S is surface planed to give a straight-line rip to provide the maximum amount of wood to work with. It sets you up with parallel edges better than rough-sawn and will save time in your shop. When you’re ready to move forward with your woodworking project plans get in touch to find out how we can help, or drop into our depot and check out our selection of premium hardwood.

The Best Wood for Outdoor Projects

Discover the best wood for outdoor projects. Learn about durable, weather-resistant options to ensure your outdoor structures last for years.

How to Seamlessly Plan A Woodworking Project

Learn how to seamlessly plan a woodworking project. Discover tips for selecting materials, designing, and organizing your workspace for smooth execution.

Best Types of Wood For Furniture Making

Wood is one of the earth's most versatile natural materials, used for anything from construction to cutlery. That wood is widely used for furniture making should be no surprise. As you might imagine some types of wood are better for furniture making than others, especially for tabletops or chairs. Our team at North Castle Hardwoods understands lumber and the needs of woodworkers. Get in touch today to see how we can help you. Explore the Beauty and Variety of Types of Wood for Furniture Hardwood has a wide range of grain patterns and colors to choose from. The deep reds and contrasting yellows of cherry wood give it extraordinary dimensional depth, while the myriad complex patterning of cat’s paw oak has its own unique character. For many woodworkers contemplating a furniture-making project, the sorting and selection of the lumber is an important part of the process. Finding the perfect coloration and matching it to the grain can take time, but it’s worth it. The pleasure of pairing lumber sections and selecting them for a cutting list certainly can feel like a voyage of discovery. What Types of Wood are Best for Furniture? There are as many opinions as to what the best types of lumber are for furniture making as there are woodworkers, but there is a general consensus that you can’t go wrong with our top five. These timbers are all readily available in North America and are guaranteed to deliver fantastic furniture results. Here they are in no particular order! Cherry Wood American black cherry wood grows extensively across the United States and can be found in most lumber yards. Prunus Serotina is its botanical name and fresh cut, its creamy yellows and deep reds draw the eye. Over time cherry darkens as it oxidizes, delivering deep three-dimensional planes of color, perfect for tabletops, countertops, dressers, and cabinets. Hard Maple Maple is a stunning, bright, close-grained material that bounces light off every surface. Strong, and resilient it is a top choice for everyday utilitarian furniture, for chairs, table legs, and elegant nightstands. The straight grain of hard maple makes it ideal for fine work too, with slender legs for stools, chairs, and display cabinets. White Oak The strength of oak is a major part of this timber’s character. It’s not exactly white but has bright flecks in its straight grain that catch the light and glint in the sun. White oak is tough as well as beautiful, and highly resistant to decay. If you are looking to create furniture that will sit on your porch, deck, or garden room, white oak may well fit the bill. The grain and figure of white oak are exceptional and can vary immensely depending on how the original lumber is processed. Cutting lumber one way produces one result, cut another, often something different, but still very special. Red Oak The sheer pleasure of working with red oak is second to none. If you’re starting out with woodworking, then red oak is a brilliant choice as it is easy to get great results from this very workable lumber. Experienced woodworkers know only too well how seductive grain patterning can be, making timber selection a joy. Walnut Walnut is the king of the forest, delivering a timeless dark color, often with deep chocolate tones. Juglans Nigra is the botanical name whether the label says American black walnut or Eastern black walnut. The luxurious deep tones of walnut have made it a favorite choice for desks and tabletops, with clear finishes making the most of its fine grain. Its dimensional stability Inspiration For Your Next Wood Furniture Project What’s missing from your home? Do you need a new nightstand, or has the dining room table seen better days? Ask any seasoned woodworker, there’s nothing more satisfying than living with a piece of furniture crafted by hand. Tables and Nightstands For a tabletop, the most important part of the project is the timber selection. Once the work is done, the tabletop should be something seen and enjoyed every day. Take your time to pick out grain and coloring that really catches your eye. Tabletops are a great way to display a fantastic piece of grain and showcase your furniture woodworking skills. Mix and match different colored hardwoods to create an eye-catching pattern, or pair lighter and darker timber from the same source, perhaps using cherry’s gorgeous yellows and reds. Chairs and Barstools For spectacular turned legs that turn heads on your chairs and tables choose a softer cherry or walnut. Both work well on a lathe, making great results achievable for the least experienced woodworker. Woodturning takes a little practice, but a lathe is a must-have for traditional furniture styles. Don’t be put off by the technical aspects, it’s a traditional art that has been developed over centuries! If you are going for a more contemporary look, say mid-20th century and up, then maple makes a great choice. Its fine, linear grain and high strength, lends itself to simplicity and elegance. Cabinets and Chests White oak and cherry wood are the traditional go-to timbers for prestige heirloom furniture that looks good and retains its value over the generations. Oak is a tough customer, so make sure your tools are honed well! Learn how to use box, or finger joints to create drawers for your dresser projects. With a little patience and time, there are no limits to your woodworking ambitions. Shelves and Bookcases Red oak is strong, straight, and sturdy enough to provide elegant support for your collection of woodworking books. If you are a big reader, and a home library is an essential feature, then red oak will not disappoint. Ordering Wood for Your Next Project Choosing the best wood for your furniture-making project is just part of the process. There are several other steps to consider along the way! Furniture Making Process Before you begin, writing up a cutting list to quantify exactly what lumber you will need is essential. Some plans come with cutting lists supplied. If you are starting out, use one of these to make sure nothing is missing. If what you plan to build is a bespoke design, then take a look at something similar to offer inspiration for your own cutting list. Excess for Success Whatever your furniture making project entails be sure to over-order. Even the most carefully selected wood will have flaws and imperfections, or grains that don’t quite fit expectations. Wood is a fantastic natural material, and even the most even grained maple will have small imperfections. To counter this, allow for approximately 20% wastage. Remember too that your project is unlikely to fit all the standard lumber sizes supplied, so expect offcuts. These can be used later for repairs, or as practice pieces, or finally, as firewood to keep the workshop warm! Store Your Wood Properly There’s nothing worse than beginning a project to find that moisture ingress has affected the wood, perhaps mold has grown, or the lumber has become twisted. Some timbers are more resilient than others but none of them appreciate over exposure to poor weather conditions. Keep your investment secure, and stored properly, so that you can be confident that your project will go well however long it takes between visits to the workshop. Heirloom Furniture-Making Projects In the garden room, there is a dining table built by my great-uncle in 1955 that he made for the kitchen in the house that he built for himself and his wife. It is an unremarkable piece of utilitarian furniture, a mix of cherry, maple, and oak, but it is beautiful nonetheless. When we start a project, to fill a current need, or simply out of fun, there’s no knowing where it will eventually land and be loved. Next Steps All our lumber at North Castle Hardwoods is selected from reliable and sustainable North American growers. Our team can hand-pick wood to your specifications. Go online and search for practical, and free, furniture-making plans. Select two or three that look good and get them downloaded to compare them. Choose a plan that has the most comprehensive information and use it as a pattern for your own project. Remember to check your measurements carefully so you are not caught short!